Researchers are developing an energy-efficient method of converting methane into carbon nanotubes

05/19/2019 / By Edsel Cook

The U.S. Department of Energy (DOE) is looking to get the most value out of the vast natural gas deposits in North America. It recently provided a big federal grant to Rice researchers, who would come up with an efficient yet inexpensive way to turn methane gas into carbon nanotubes.

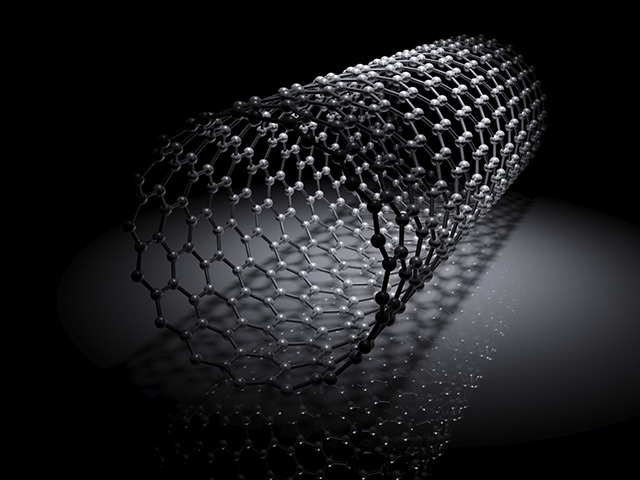

Being an allotrope, or alternative form of carbon with cylindrically arranged molecules, carbon nanotubes boast many new and unique properties that make them very useful. They are strong enough to serve as potential replacements for metals like steel and titanium, traditional materials that are expensive to extract from mines and even more costly to refine into alloys.

The task of the Rice University-led research group is to develop an energy-efficient process of producing carbon nanotubes out of natural gas. Once they succeed in turning methane into the carbon allotrope, the researchers will weave them into fibers before running a series of tests on the nanotubes’ ability to fill the boots of metal materials.

Their funding comes from the OPEN+ program of the DOE’s Advanced Research Projects Agency-Energy (ARPA-E). The federal agency is currently investing in potential breakthrough development for concrete and methane-related technologies. (Related: The next asbestos? Carbon nanotubes, used in manufacturing, linked with cancer risk.)

Coming up with an energy-efficient way to turn natural gas into carbon nanotubes

The end goal for the research is to replace metals with carbon nanotubes in all kinds of applications. Switching to carbon allotropes will reduce the amount of energy expended by the metal-making industry. It will also cut back on the air pollution generated by the process of refining metal.

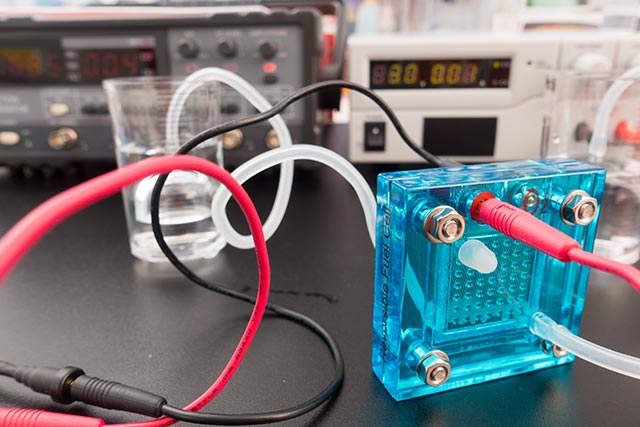

Last but not least, the process creates hydrogen gas as a byproduct. Hydrogen itself can serve in many ways, including providing clean energy through fuel cell engines.

The leader of the research group, Rice professor Matteo Pasquali, explained that humans considered carbon to be a source of raw materials for the vast majority of human history and civilization. The ongoing use of fossil hydrocarbon as an expendable source of fuel for producing energy only came about two hundred years ago.

Furthermore, the current carbon economy spent much of that energy on producing aluminum, copper, steel, and other metals. But these materials were described to be inefficient in terms of the energy expended to make massive amounts of them.

Pasquali claimed that the mining and production of metals accounted for more than 10 percent of the energy used by the entire world every year. Metal production is also to blame for a similar percentage of the world’s air pollution.

A carbon-based replacement for expensive and polluting metals

The Rice researchers believe that directly converting natural gas into carbon nanotubes can bring numerous benefits. The carbon allotrope is lighter than the metals it will replace, thereby producing considerable weight savings.

The planned use of a hydrocarbon decomposition method will generate large amounts of hydrogen. The gas can be burned as a clean fuel to reduce the costs of producing carbon nanotubes. Hydrogen is also easy to store and transport, so it can go to wherever it was needed.

Finally, the carbon conversion process needs to be very efficient. Pasquali predicted the need to produce hundreds of megatons of carbon nanotubes every year.

“Realizing this vision will require creating new value chains, supply chains and manufacturing chains, as is always the case when a new class of materials is introduced,” he said in a press release. “Such an effort will require decades to reach full deployment and will require partnering with multiple other organizations both at the stages of materials synthesis and conversion as well as in manufacturing and introduction into products.”

Sources include:

Tagged Under: alternative materials, breakthrough, carbon nanotubes, Chemistry, Clean Energy, cool science, discoveries, energy conservation, green living, hydrogen, innovation, materials research, materials science, metals, Methane, natural gas, new materials, physics

RECENT NEWS & ARTICLES

COPYRIGHT © 2017 CHEMISTRY NEWS