From tires to shoes, disposable rubber items may soon be able to self-repair

07/16/2019 / By Edsel Cook

Rubber items may one day be able to regenerate any damage they incur from everyday wear and tear, plus the occasional accident. California-based researchers developed a self-repairing rubber material that’s compatible with 3D printing methods.

Qiming Wang led the University of Southern California (USC) research team. An assistant professor at the USC’s Viterbi School of Engineering, Wang is also involved in creating new functions for 3D-printed materials.

For his latest work, Wang worked together with Viterbi students and his University of Connecticut (UConn) counterpart, Assistant Professor Ying Li.

They developed a new material that lends itself well to rapid manufacture. The rubber also has the ability to repair any fractures or punctures it sustains.

The new self-repairing material could revolutionize rubber-based industries, including electronics, shoes, soft robotics, and tires. Its developers believe it can reduce manufacturing time and improve the durability and longevity of these products. (Related: Carbon is GOOD: MIT chemical engineers create a material that can repair itself using carbon from the air.)

Finding the right ratio between ease of 3D printing and material chemistry

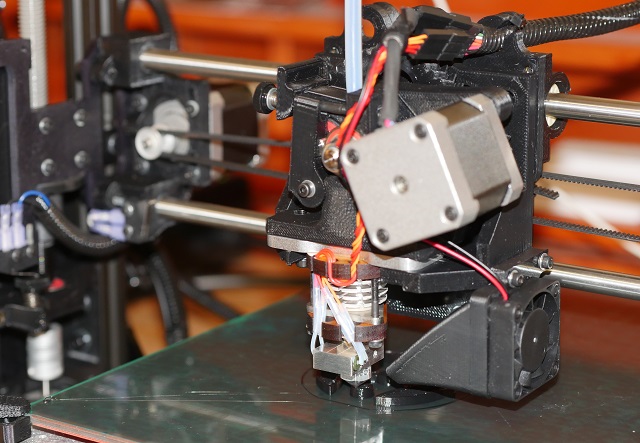

The USC-UConn researchers produced the self-repairing material using a kind of 3D printing technology called photopolymerization. This process makes use of light to mold a liquid resin into a specific geometry or shape.

However, giving the material the ability to repair itself required a different approach. The researchers had to tweak the chemical composition of the material to enable it to self-repair and allow rapid photopolymerization.

Thiols are a chemical group necessary for photopolymerization. When they come into contact with an oxidizer, they transform into a different group called disulfides. Disulfides are capable of reforming themselves when they get broken. Their self-repairing ability was what the researchers wanted to incorporate into their new material.

Unfortunately, finding the right ratio between thiols and disulfides wasn’t easy. Increasing the number of disulfides made the material better at self-repair but also made it difficult to produce.

Wang and his team experimented with various ratios. They looked for a middle ground between ease of manufacture and self-repairing.

“When we gradually increase the oxidant, the self-healing behavior becomes stronger, but the photopolymerization behavior becomes weaker,” Wang said. “And eventually we found the ratio that can enable both high self-healing and relatively rapid photopolymerization.”

A 3D-printed rubber material that repairs damage in hours

With the correct formula for the self-repairing material, it only took the researchers five seconds to print a small square. Bigger printing jobs took about 20 minutes.

The researchers showed the material’s ability by manufacturing an electronic sensor, a multiphase composite, a shoe pad, a soft robot, and other items using the material. All of the products proved capable of repairing themselves within a few hours of incurring damage.

When the researchers cut them in half and measured the time it took for them to repair themselves at 140 degrees Fahrenheit (60 degrees Celsius), they found that non-electronic products took two hours to self-repair. The electronic items needed four hours because they used carbon for transmitting electricity. Their repair time is heavily influenced by temperature.

“We actually show that under different temperatures – from 40 degrees Celsius to 60 degrees Celsius – the material can heal to almost 100 percent,” said USC structural engineering student Kunhao Yu, the primary author of the study. “By changing the temperature, we can manipulate the healing speed, even under room temperature the material can still self-heal.”

The team is now busy developing more self-repairing materials with varying stiffness. They want to produce self-healing hard plastics for rigid shapes like body armor, composite materials, and vehicle parts next.

Sources include:

Tagged Under: 3D printing, breakthrough, discovery, disulfides, electronics, future science, goodtech, innovations, inventions, new materials, photopolymerization, plastics, rapid manufacturing, research, Rubber, rubber-based industries, science and technology, self-healing material, self-repairing material, technology, thiols

RECENT NEWS & ARTICLES

COPYRIGHT © 2017 CHEMISTRY NEWS